Industry: mobility

- Automotive (vehicle construction)

- Public transport (train, bus & tram)

- shipbuilding

- aviation

1. Felt for the industry: Automotive (vehicle construction)

Find out how our high-quality industrial felt takes vehicle acoustics and comfort to a new level.

Versatile applications in vehicle construction:

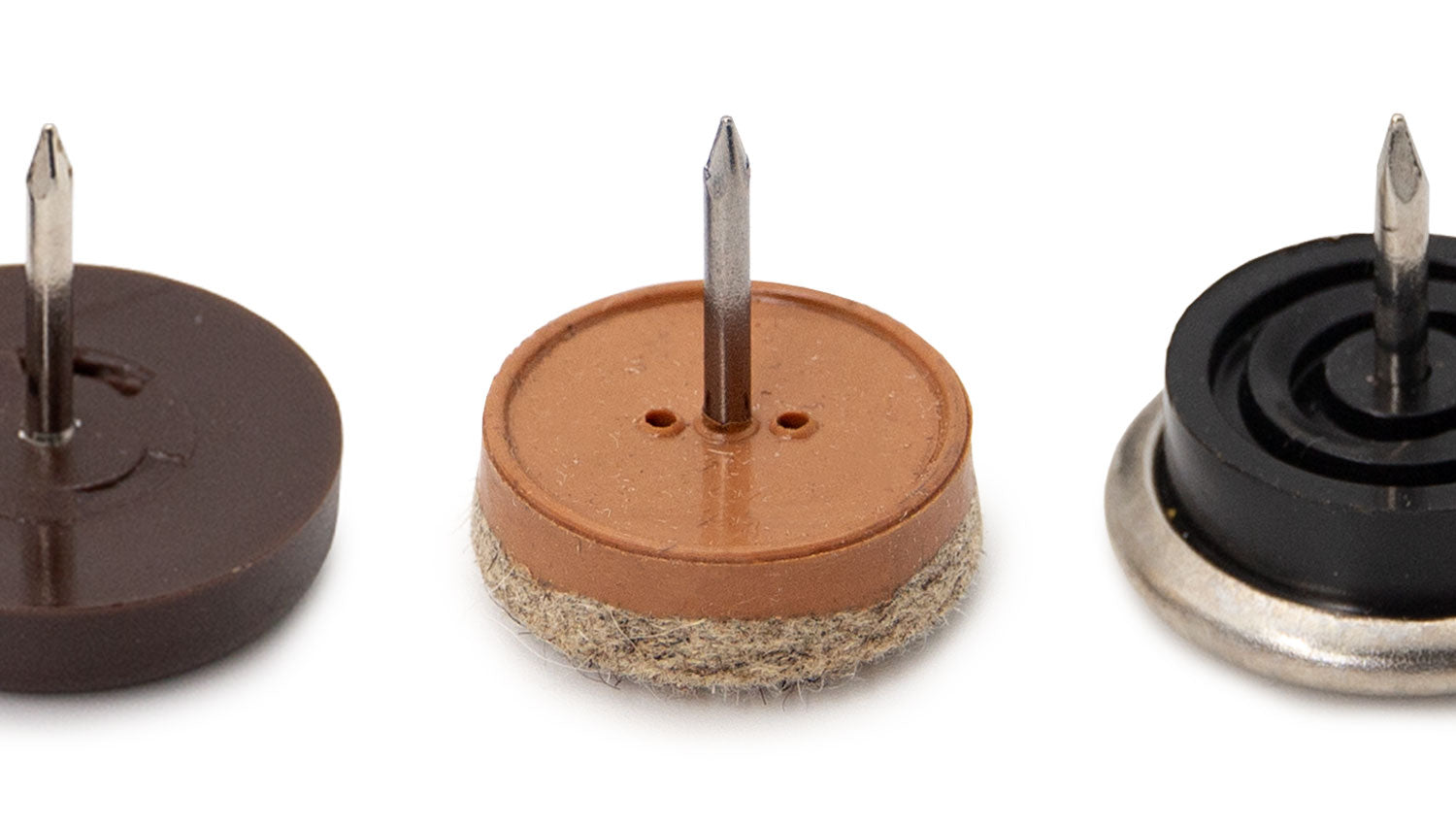

- Cuts for spare wheel cover/lining for special installations – also self-adhesive

- Molded and stamped parts on side panel insulation to reduce noise

- Pads on A, B and C pillars (anti-squeak and anti-rattle measure)

- Felt strips or padding on metal structures/seat frame/seat components

- Self-adhesive felt pads to prevent squeaking and rattling on plastic injection molded parts of the interior lining

- Center console insulation/insulation

- Molded and stamped parts as glove compartment covers

- Self-adhesive felt strips on instrument panel components (anti-squeak and anti-rattle measure)

- Padding on the underside of gearshift and handbrake levers (rattle prevention)

- Insulating material for door pockets

- Kick protection pads on door cutouts

- Molded and stamped parts as cladding and insulation for the A, B and C pillars

- Molded and stamped parts as insulation to reduce noise in the doors

Improved vehicle acoustics for greater comfort

Our industrial felt plays a crucial role in the mobility industry, particularly in noise reduction and vibration dampening in vehicles. With our innovative felt technology, we offer acoustic solutions that improve vehicle comfort and create a quieter, more pleasant driving environment.

Effective noise reduction and vibration dampening

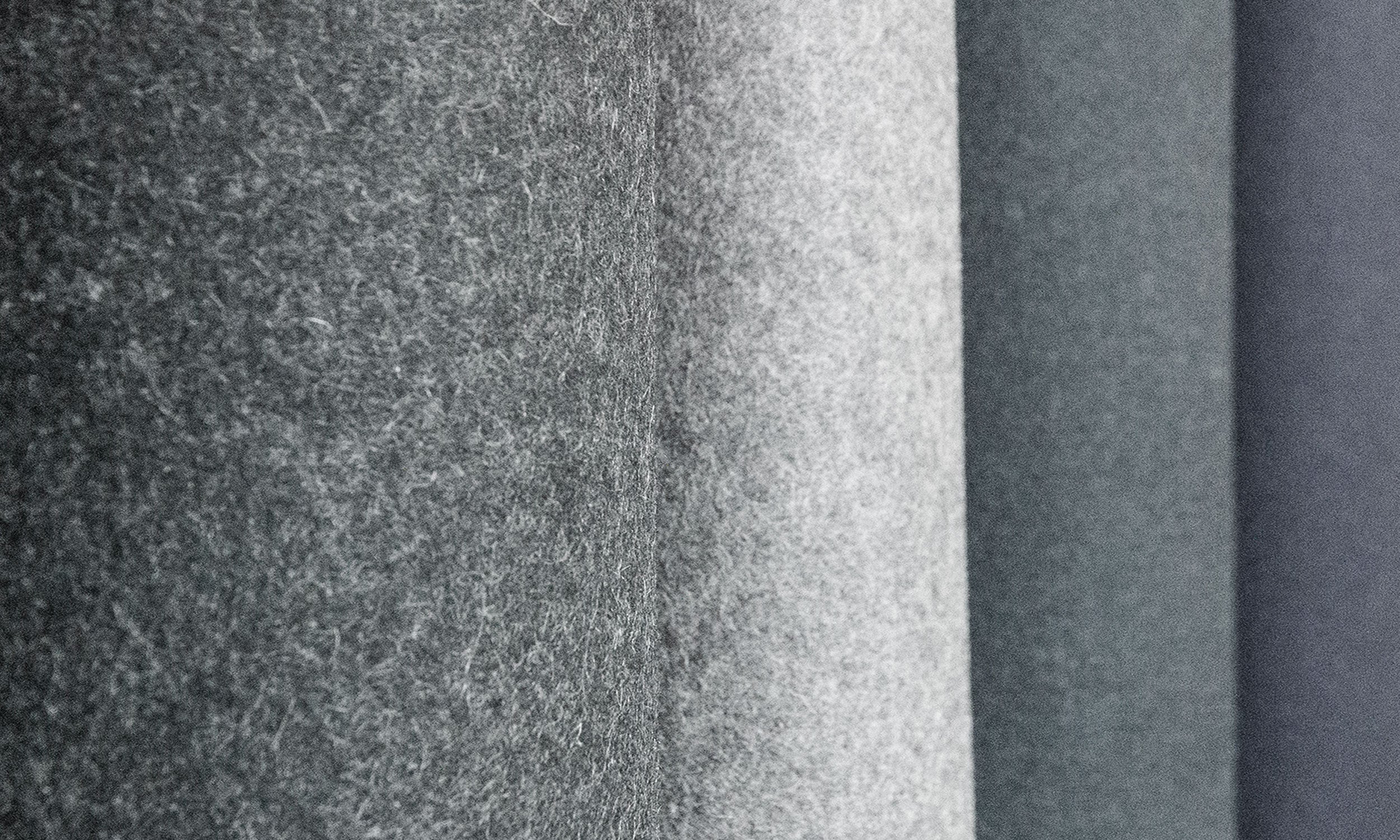

One of the biggest challenges in the automotive industry is the annoying noise and vibration levels while driving. This is where our high-quality industrial felt comes into play. Thanks to its special composition and structure, it effectively absorbs noise and minimizes vibrations. The result? A significant reduction in vehicle noise and a smoother, more comfortable ride for occupants.

Versatile applications in vehicle interiors

Our felt products are not only used for vehicle insulation, but also in vehicle interiors. From dashboards to door panels to seats and trunk liners, industrial felt has a variety of applications to improve the comfort and quality of vehicle interiors. Our sustainable felt materials contribute to sound insulation and ensure a pleasant atmosphere in the vehicle.

High quality felt manufacturing and processing

We are proud to produce high quality industrial felt for the mobility industry. Our felts are manufactured using the latest processing techniques to ensure excellent quality and durability. As experts in felt production and processing, we offer tailor-made solutions that meet the specific requirements of our customers.

Tailor-made solutions for individual requirements

For us, customer satisfaction is our top priority. Our team of experienced professionals will work closely with you to develop the best felting applications for your individual needs. We are committed to providing you with the highest quality and efficiency.

Contact us today to find out more about our industrial felt products and their potential uses in the mobility industry. Our felt technology will exceed your expectations and take your vehicles to new levels of noise reduction and vibration dampening.

Discover our wide range of industrial felt products for the mobility industry. From high-quality insulation materials to innovative felt solutions for vehicle interiors, we offer products that are focused on quality, sustainability and efficiency. Find out how our industrial felt can improve the mobility experience and contact us to find out more.

Due to the wide range of possible uses, all automobile manufacturers use felt in different ways, preferably in and on interior components such as the seats or armrests, on instrument panels and all associated components such as vents, flaps and compartments. Technical felts are also used in the headliner, doors or kinetic assemblies of the interior.

2. Felt for the industry: Public transport (train, bus & tram)

Innovative felt solutions for rail vehicle and wagon construction: focus on comfort, safety and aesthetics.

Rail vehicle and wagon construction

The comfort for passengers in passenger rail vehicles is continually improving, similar to that in automobile manufacturing. In addition to advanced chassis and modern plastics as wall and ceiling systems, the acoustic requirements also represent a growing challenge.

As travel speed increases, annoying noises arise, which is why sound-absorbing and insulating measures are necessary. Our felt parts close gaps, decouple the installed elements from each other and thus reduce squeaking and rattling noises (BSR - buzz, squeak and rattle).

In the right places, our products ensure a pleasant travel climate! Different material combinations are used that are manufactured sustainably and in an environmentally friendly manner.

High passenger safety is very important in rail transport. We are therefore working on introducing additional test procedures (including according to DIN EN 45545-2, fire behavior).

Our product selection includes:

- Felt strips : sound absorption of external noise, noise insulation for indoor use, insulation strips for thermal insulation.

- Filter felts : for air and liquids.

- Felt plugs : for dosing primer liquids to prepare adhesive surfaces, for applying adhesives when installing panes or connecting ceiling and wall panels.

- Felt squeegee, foil squeegee : for applying decorative strips or decorative films with felt squeegees, covering (protective) films on railcars, signs, etc. (product information for download).

- Punched parts, also self-adhesive : according to your specifications (drawing, sketch, pattern).

- Carpet felts : for lining luggage compartments or loading floors.

These products support the needs of rail transport and help improve passenger conditions.

Felt in buses and trains

- Sound insulation and noise reduction : Felt parts are used to block unwanted noise from outside sources and make the interior of buses and trains quieter. By placing felt strips in critical areas, squeaking and rattling noises can be minimized.

- Acoustic improvement : Modern plastics combined with felt can be used as complete wall and ceiling systems to optimize the acoustics in the interior of buses and trains. This helps reduce noise levels and creates a more comfortable travel environment for passengers.

- Thermal insulation : Felt insulation strips are used to provide thermal insulation in buses and trains. They help reduce heat transfer and maintain a comfortable internal temperature.

- Felt Plugs and Gaskets : Felt is used as a material for plugs and gaskets to seal gaps and minimize vibration. This prevents unwanted air and noise from entering.

- Carpet Felts : Felts are used to line overhead compartments or cargo floors to protect luggage and cargo and provide a non-slip surface.

This product selection contributes to improving comfort, safety and aesthetics in buses and trains by meeting the specific needs of public transport.

3. Felt in shipbuilding

Innovative felt solutions for shipbuilding: comfort, protection and quality in the maritime environment.

Felt solutions for shipbuilding: challenges and priorities

Various challenges come together in shipbuilding. On the one hand, it is important to absorb condensation and prevent odors and mold from forming. On the other hand, fire protection is a top priority, despite the high water presence around the ship.

Versatile felt materials: adaptability and safety

In this context, technical wool felts and needle felts play an important role. These materials can be customized to specific requirements. They are rot-proof, flame-retardant, elastic and easy to process. This means they can be easily pulled around any edge or corner.

Functional properties in shipbuilding: insulation, padding and more

Our products in shipbuilding fulfill various functions:

- Cold insulation and thermal insulation for passengers' comfort.

- Padding and protection for the safe transport of goods.

- Effective sound insulation to reduce annoying noises.

- Moisture regulation to ensure an optimal environment.

Use of felts in motorboats and sailing yachts

Felts are also used in the manufacture of motorboats and sailing yachts, be it when priming surfaces or when using felt squeegees.

Decoupling and insulation: Felt applications in interior design

In interior construction, felts are used on the edges of components to decouple vibrations. When attached to the hull, they provide cold insulation and sound insulation behind Dec

ken and wall panels. These specially equipped felts are weather-resistant and absorb only a small amount of moisture.

Versatile areas of application: primer felts and felt squeegees

Primer felts are used for cleaning and chemical activation of adhesive surfaces during the assembly of deck and hull superstructures or for the assembly of fixed glazing or portholes. Our felt squeegees enable the bubble-free application of self-adhesive films, ship names or decorations indoors and outdoors.

Improving passenger conditions: felt solutions for shipbuilding

With our versatile felt solutions, we help overcome the challenges in shipbuilding and improve passenger conditions.

4. Felt in aviation

In the aviation industry, the focus is on the relationship between minimum weight and maximum resilience of the materials used. Particular attention is paid to fire protection.

Diverse felt processing for aviation

We process various synthetic materials such as polyester, polyamide, aramid needle felts and others. Based on our customers' specific requirements, we select appropriate materials and processes to ensure optimal solutions for each application. Our technical felts and felt products are available both as rolls and ready-made.

Reliability and certifications for the aviation industry

Reliability and trust form the basis for long-term cooperation. The aviation industry places high demands on suppliers, particularly in terms of materials, quality and environmental management. Our production is certified according to the IATF 16949 and DIN 14001 standards. Of course, we also work to meet the standards for the fire behavior of materials and components in aviation.

Applications of felts in aviation

Our felt products are used in various aviation applications including:

- Primer felts for preparing adhesive surfaces for windows or chassis/hull/add-on parts

- Felt strips for decoupling ceiling and wall panels to reduce annoying noise

- Felt strips to reduce noise on cable harnesses/cable harnesses

- Insulating felts to insulate the cabins

With our high-quality felt solutions, we meet the specific requirements of the aviation industry and contribute to safety and efficiency in aviation.