As an industrial customer requiring felt for your applications, it is important to understand that felt is available in different types. Selecting the right type of felt is critical to the functionality and performance of your applications. In this blog post we will introduce you to the different types of felt and their properties.

1. Felt designations according to material

2. Felt designations according to area of application

1. Felt designations according to material

wool felt

Wool felt is one of the oldest and best known types of felt. It is made from sheep's wool (viscose is added depending on the quality) and is a very durable material that is known for its thermal insulation, sound insulation and padding. Wool felt is also an environmentally friendly material as it is biodegradable and recyclable

Needle felt

Needle felt is a type of felt made using the needle felting process. The material is pierced with special needles, causing it to compact. Needle felt is produced in various densities and thicknesses and is particularly suitable for its sound insulation and padding.

The following fibers can be processed:

Meta-aramid (Nomex)

Para-aramid (Kevlar)

synthetic chamois

Polypropylene

polyester

Wool

Synthetic felt (=always needle felt)

Synthetic felt is made from synthetic materials such as polyester, polypropylene or nylon. It is available in various strengths and thicknesses and can be used for various applications such as padding, sound insulation, thermal insulation and sealing materials. Synthetic felt is water-repellent and resistant to chemicals.

fleece

Fleece is a very light and thin felt material made from synthetic or natural fibers. It is manufactured in various densities and thicknesses and can be used for various applications such as padding, sound insulation and filters. Non-woven is a cost-effective material and easy to process.

2. Felt designations according to area of application

What is saddle felt?

Saddle felt is felt used in saddlery, particularly for padding saddles and other equestrian equipment. It provides comfort and shock absorption for rider and horse.

Saddle felt for acoustic insulation

is used in recording studios or recording rooms to reduce sound reflections and achieve better sound quality

Saddle felt for crafts and crafts

is often used in craft projects, such as making felt toys, dolls, keychains or ornaments

What is brake felt?

Brake felt is felt used in the brake industry. It is often used in brake pads to create friction and improve braking performance. Brake felt is wear-resistant and heat-resistant.

Brake felt in mechanical engineering

is used to dampen noise or protect sensitive surfaces in machines

Brake felt in transport

used in trains, planes or boats to reduce friction and wear

What is damper felt?

Damper felt is felt used to reduce vibration, shock and noise. It is often used in the automotive industry to dampen vibrations and noise and ensure a quieter ride.

Damper felt in electronics

Damper felt is often used in the electronics industry to absorb vibrations and shocks and protect sensitive electronic components from damage.

Damper felt in construction

Damper felt can be used in buildings to dampen vibrations and noise, for example when installing elevators or in soundproof walls

What is trim felt?

Trim felt for costume design

Trim felt for interior decoration

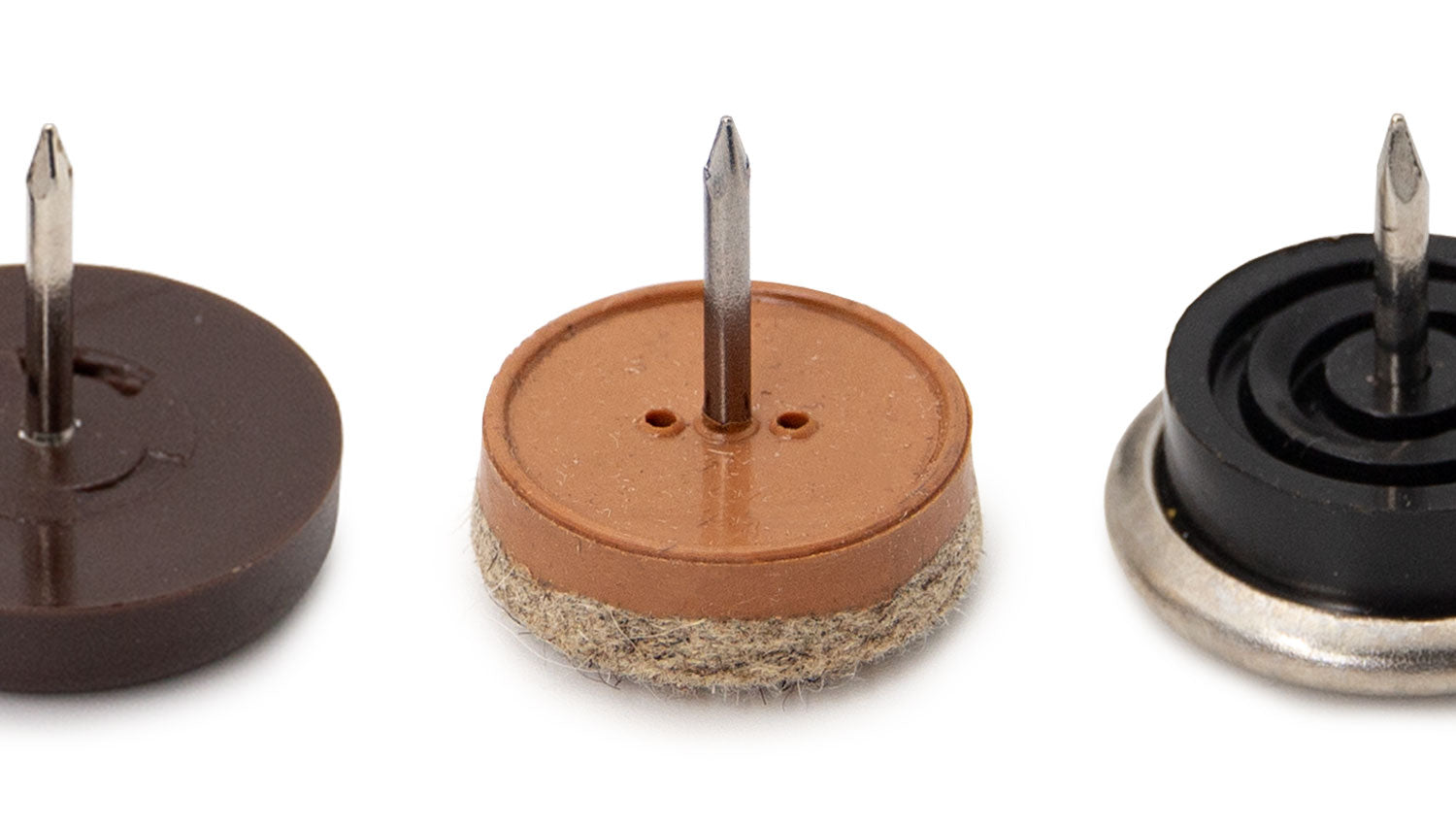

What is upholstery felt?

Upholstery felt is felt used to upholster furniture, chairs, sofas and other seating. It provides comfort, elasticity and support and helps make seating surfaces softer and more comfortable.

Upholstery felt in the automotive industry

Upholstery felt is used in the automotive industry to upholster car seats, armrests or headliners and to ensure comfort while driving.

Padding felt in medical care

In the medical industry, padding felt can be used in the manufacture of orthopedic devices such as mattresses or seat cushions to minimize pressure points and provide comfort.

What is lining felt?

Lining felt is felt that is characterized by its excellent heat regulation and is therefore perfect for the shoe and clothing industry. It also has sound-absorbing properties that make it the ideal noise damper in the automotive industry.

In addition to these outstanding features, lining felt offers other concrete advantages. It is slightly compacted and is available in different thicknesses, which allows it to be adapted to specific requirements. The variable wool content of the lining felt is another plus point, as it can be adjusted as needed.

Lining felt in handbags

Lining felt is often used in the manufacture of handbags to protect the interior of the bags and keep items from being scratched or damaged.

Lining felt in slippers

Lining felt can also be used in the manufacture of slippers or slippers to provide warmth and comfort to the feet.