We regularly receive questions from customers about our felt products and their use. In this article, we've summarized and answered some of the most common questions to help you choose the right felt for your project. Read on to find out more!

Table of contents

01. What common uses does felt have?

02. How is felt made?

03. What is felt made of?

04. What is the difference between industrial felts?

05. Are there color variations between felts?

06. Is felt washable / Can you wash felt?

07. Can felt be used for sound insulation?

08. Is felt flame retardant?

09. Is felt absorbent?

10. If felt is cut, will it fray?

1. What common uses does felt have?

- Crafts and DIY Projects:

Felt bags , jewelry , decorations and toys

- Footwear and clothing industry:

Shoes , winter clothing such as coats , jackets and boots

- Technical applications:

Seals , insulating material , dampers or filters

- Furniture and interior design:

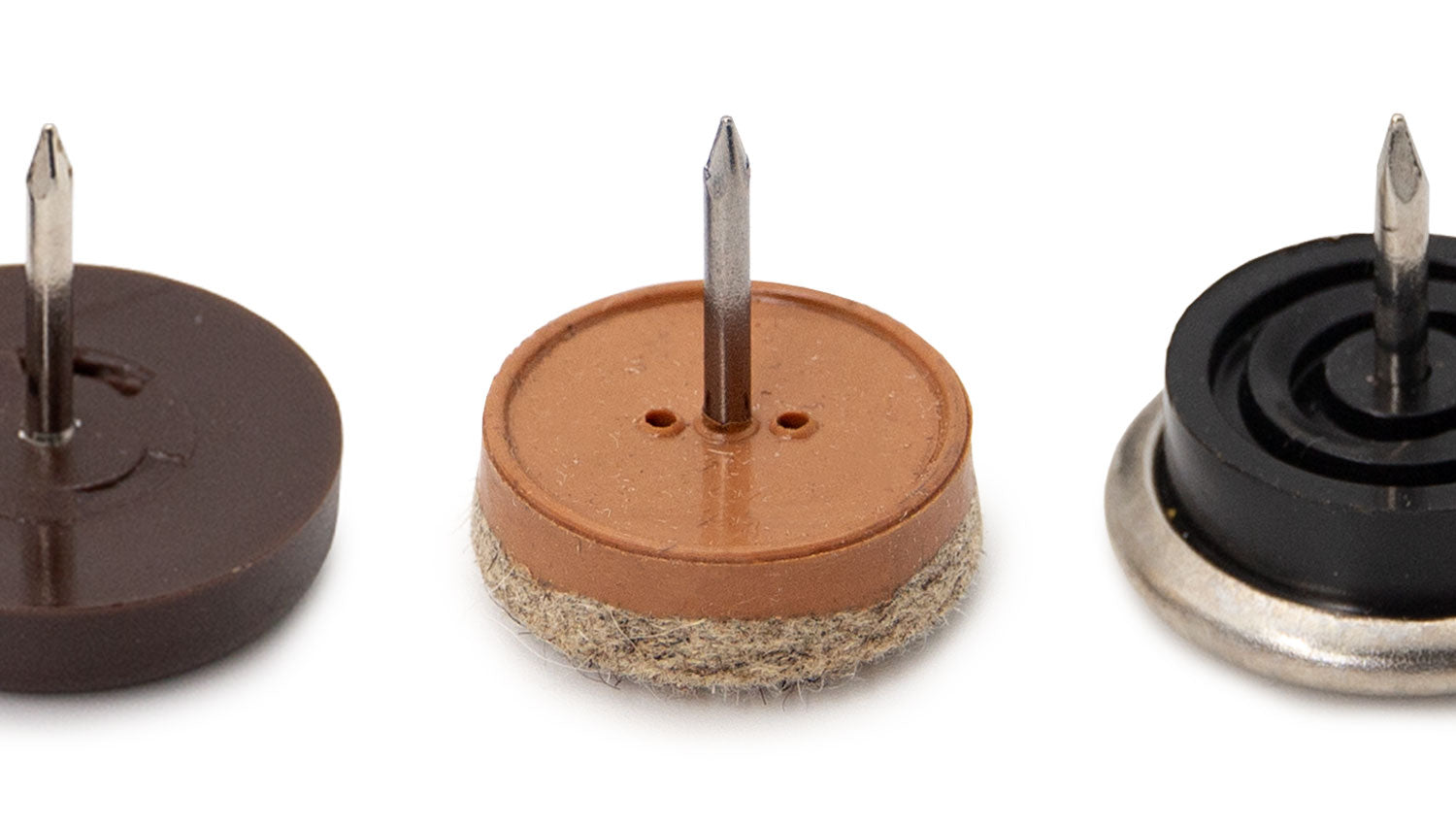

Furniture gliders, upholstery material , carpets or wall coverings

- Musical instruments (especially keyboard instruments):

Felt for pianos , organs and accordions

The use of felt is very broad, ranging from craft applications to technical and industrial applications . It is a versatile material with many useful properties that is used in a variety of projects and industries .

2. How is felt made?

Felt is made by matting animal hair or synthetic fibers.

When making felt from animal hair, wool obtained by shearing sheep is usually used. The wool is cleaned , washed and combed to remove dirt, grease and other impurities .

The wool is then treated with soap and water (manual) or heat (machine) and worked either by hand or machine to entangle the fibers . This creates a dense fabric that does not fray and is very durable. (see glossary: wool felt)

Synthetic felt is made from polyester or acrylic fibers . The fibers are processed by needling , chemical or thermal processes . (see glossary: needle felt)

When needling, the fibers are connected to each other using barbed needles. This is a purely mechanical process!

In thermal processes, the loose fibers run through an oven where they thermally bond. The thermal bonding can be done by the fiber itself (melting temperature) or by a chemical binder.

Chemical processes bind the fibers by utilizing the chemical binder by reacting with light, heat, moisture or solutions to bond the fibers together.

Making felt requires a lot of experience and expertise to achieve a high quality end product.

3. What is felt made of?

High-quality felt is made of wool .

Felt can either be 100% wool or contain a blend of wool and other materials.

Felt can be made from many different fibers or a specific fiber. Depending on the quality and intended use, different materials can be used.

Mixture of fibers

Felt, which is made from a mixture of fibers, can contain various components. These can be recycled wool (e.g. old sweaters), recyclable fibers, viscose/rayon (a wood fiber) or occasionally polyester.

Use of synthetic fibers

In addition to natural fibers, felt can also be made from synthetic fibers such as acrylic. This type of felt is typically used in craft projects.

4. What is the difference between the industrial felts?

General differences between industrial felts

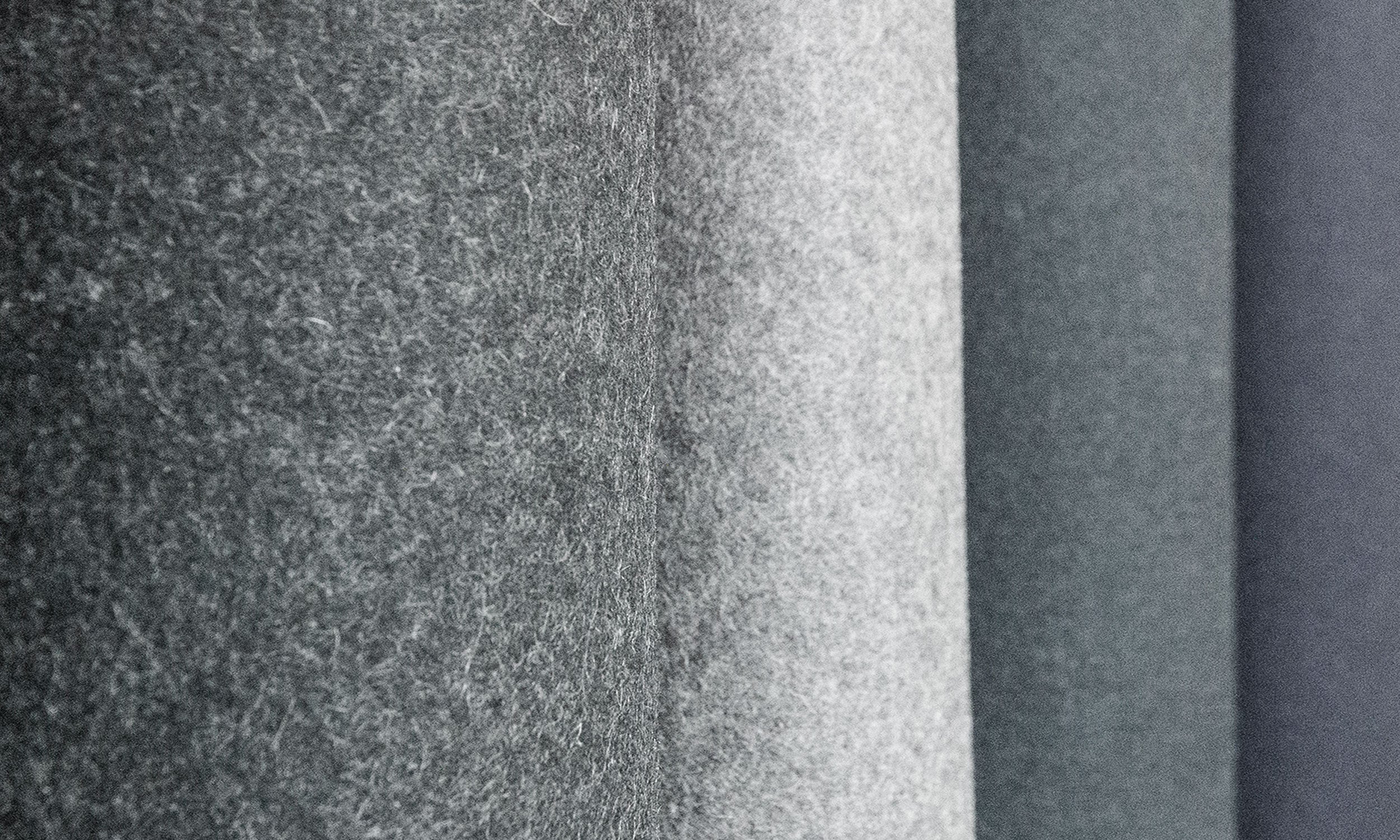

Color differences and nuances of natural wool bales

The color nuances of industrial felts cannot be guaranteed during the production process. This is because they depend on the natural bales of wool used to make the felt. Each batch can therefore be significantly different.

Differences between white and gray wool

White wool is considered to be of higher quality and more durable than gray wool. These differences in quality can affect the uses of the felt.

Natural colors and possible irregularities

Industrial felts are generally not dyed and retain their natural colors. These range from a light beige to dark browns and grays.

Our 0.20 kg/cdm felt:

Sold by the meter - soft wool felt

Felt sheets - soft wool felt

Felt with a density of 0.20 kg/cdm is often used in industrial applications where a certain density and strength is required. Here are some examples of what felt with a density of 0.20 kg/cdm can be used for:

Precision padding

Due to its specific density, felt with a density of 0.20 kg/cdm is well suited as a cushioning material for sensitive devices or components where precise cushioning and shock resistance is required.

Soundproofing and noise insulation

Felt with this density can be used in acoustic applications to absorb sound waves and reduce noise. It is often used in recording studios, theater stages or industrial environments.

Filtration

Felt with a density of 0.20 kg/cdm can also be used for precision filtration applications where particles of a specific size need to be removed efficiently. It finds application in air filtration, liquid filtration or industrial filtration.

High quality packaging

This felt can also be used for high-quality packaging purposes to protect delicate products or components from impact or damage. It offers a good combination of cushioning and firmness.

These applications are provided as examples, and the actual uses of 0.20 kg/cdm felt may vary depending on the specific requirements and needs in different industries.

Our 0.36 kg/cdm felt :

Sold by the meter - solid wool felt

Felt sheets - solid wool felt

Felt with a density of 0.36 kg/cdm is often used in industrial applications where medium strength and rigidity are required. Here are some examples of what felt with a density of 0.36 kg/cdm can be used for:

Seals and damping material

Felt with this density can be used as a sealing material in various industrial sectors to prevent leaks or dampen vibrations.

Polishing and cleaning pads

Because of its medium strength, felt with this density makes a good polishing or cleaning pad. It can be used in metalworking, woodworking or electronics industries to smooth surfaces or remove dirt.

Felt pads and spacers

In the furniture and appliance industry, pieces of felt with this density can be used as gliders or spacers. They help prevent scratches and reduce noise.

Soundproofing and insulation

Felt with this density can also be used in acoustic applications to dampen noise or as thermal insulation.

These uses are provided as examples, and the actual applications of 0.36 kg/cdm density felt may vary depending on the specific requirements and needs in different industries.

5. Are there color variations between felts?

Yes, there are color variations between felts.

We recommend customers not to rely solely on screen representations of our felt colors. Different computer monitors may vary in color calibration.

The colors of industrial (natural) felts change depending on wool blends and compositions.

6. Is felt washable? (Can you wash felt?)

Yes, felt is washable as long as you follow a few guidelines. (Yes, you can wash felt.)

You can dry clean, hand wash or steam clean the felt, but it should not be put in the washing machine or dryer .

How do you dry felt afterwards?

- Air dry the felt.

- Dry the felt with an iron on low heat. Be careful not to leave the iron in one place for too long to avoid damaging the felt.

- Dry the felt in the oven at a very low temperature, for example 50 degrees Celsius. Leave the oven door slightly open to allow moisture to escape. Monitor the felt regularly to ensure it does not overheat or burn.

We recommend treating the felt like a wool sweater and it will last a lifetime.

7. Can felt be used for sound insulation?

Yes, felt can be used for soundproofing.

Felt is an excellent way to absorb sound and create a specific acoustic environment for private or commercial spaces. These spaces include theaters, recording studios, bars, hotels, offices and conference rooms.

8. Is felt flame retardant?

Yes, felt is flame retardant. (depending on felt quality)

Wool has a natural fire protection ability and is self-extinguishing.

Our wool felts may meet commercial fire safety regulations, while our synthetic and blended felts may require a fire safety treatment.

Please feel free to contact us about this! Directly to the contact form .

9. Is felt absorbent?

Yes, felt is absorbent.

Felt can be very absorbent and can hold liquids many times its own weight.

Wool fibers are naturally water-repellent due to the oil content (wool fat) and therefore must be washed before felting.

Different densities and qualities of felt play an important role in its absorption capabilities.

So take a look at our different types of felt for more information about which one is best for your needs.

10. If felt is cut, will it fray?

No, felt will not fray.

Felt is made by the process “needle felting” or by “wet felting”. The fibers are matted together. The edges of the felt can be cut cleanly without creating fringes.